![]() 400-850-1759

400-850-1759![]() China

China

![]() 400-850-1759

400-850-1759![]() China

China

Yanmao Intelligent Equipment (Suzhou) Co., Ltd.

Contact: Ren Hongbing

Mobile: 18016000798

Landline: 0512-53635091

Fax: 0512-53635090

QQ: 18016000798

Website: lqhgw.com

Address: No.8, Xingsheng Industrial Park, 11 Xingye South Road, Taicang City, Jiangsu Province

This machine is our company in foreign advanced technology, based on the independent research and development of new high-speed automated packaging equipment. The main configuration and features of the aircraft:

Self-control advanced: The machine adopts Siemens PLC centralized control system combined with the man-machine interface, improved a variety of control functions wrapped, the key points are set to monitor the electronic device.

High production efficiency: The main drive using the imported SEW reducer and polymer, self-lubricating, low-wear engineering plastic chain, automatic central lubrication system, stable work, low noise, high productivity.

Simple operation: The machine is fully automatic production, and equipped with frequency converter and servo controller to automatically adjust the production speed, synchronous operation with the entire production line.

Reliable hot melt adhesive equipment: The machine uses the world's leading NORDSON hot melt adhesive equipment, easy to operate, durable. After its packaging products, shape stiff, beautiful, convenient storage.

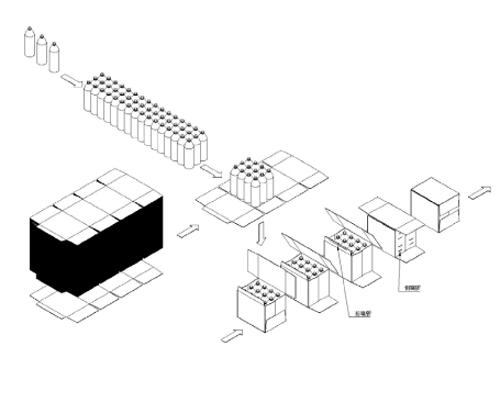

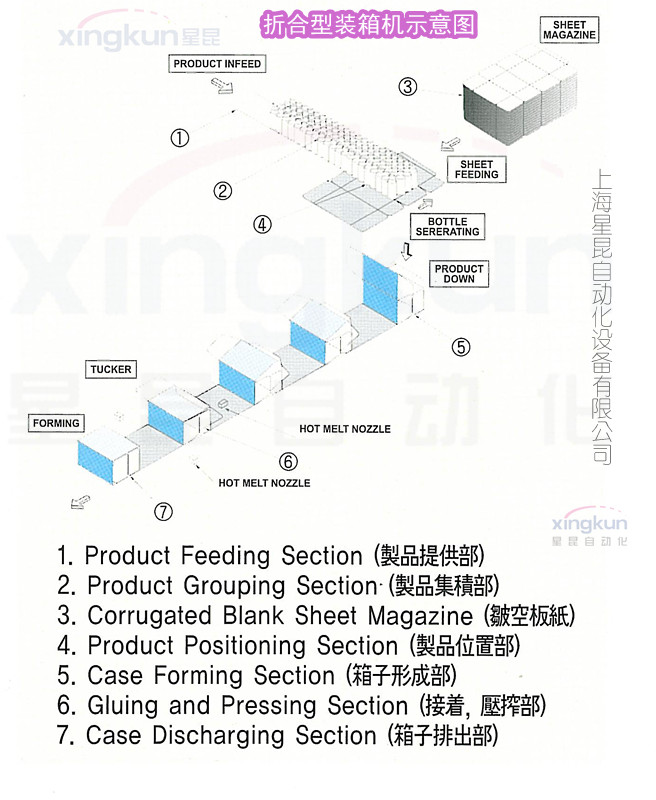

Reasonable structure: the container into the bottle conveyor belt is divided into multiple lines on the conveyor belt, and then divided by the bottle body evenly. After the containers are grouped, they fall onto the board through the bottle dropping mechanism. In the process of falling bodies with bottles and cardboard descending, the paperboard is folded into a cardboard box through a set of forming baffles. In the main drive with a luggage forward at the same time, first through the glue-spray mechanism to complete the top of the paper spray glue, and then by the cam mechanism to the top edge of the fold, while pressing the top pressure box to complete the top of the adhesion; luggage continue to move forward, Through the glue spraying mechanism, the glue on the side of the paper package is completed, and the final forming and bonding of the paper package is completed by the side pressure and the back pressure box mechanism, and the paper package is sent out by the main drive to the conveyor belt

It can be used for the packing of the beer, liquor production line and the final packing process of the production line.It can also be used for the packaging of cigarette boxes, soap, instant noodles, canned beverages, beer, white wine, soy sauce and so on.

machine type | XKWAC-60H | ||

Power / Power | 220V/380V 50/60HZ 10KW | Control power | DC24V |

Suitable carton | L200-450*W150-350*H80-350mm | Nozzle pressure | 0.4Mpa |

Packaging speed | 20-60箱/分鐘 | Consumption of plastic volume | ≤4g/箱 |

Table height | 750±50mm | Melt temperature | 170℃±5℃ |

Use gas source | 6-7kg | Hot glue melt curing time | 1.5S~2.5S |

Machine size | 8000*2200*2000mm | weight | 2600kg |