![]() 400-850-1759

400-850-1759![]() China

China

![]() 400-850-1759

400-850-1759![]() China

China

Yanmao Intelligent Equipment (Suzhou) Co., Ltd.

Contact: Ren Hongbing

Mobile: 18016000798

Landline: 0512-53635091

Fax: 0512-53635090

QQ: 18016000798

Website: lqhgw.com

Address: No.8, Xingsheng Industrial Park, 11 Xingye South Road, Taicang City, Jiangsu Province

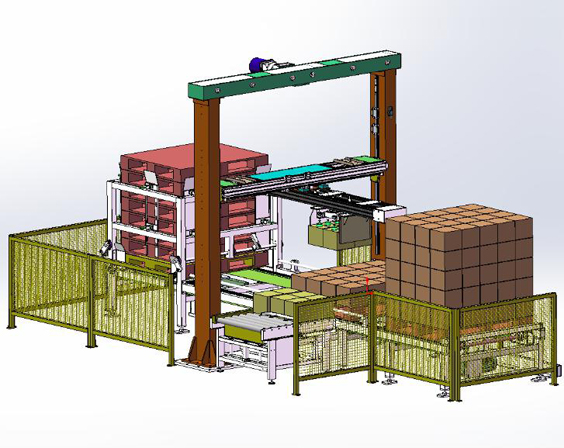

The palletizer Mao-patented product, a low-coordinate palletizing machine is loaded into the container carton, according to a certain array of code on the tray (plastic or wood), automatic stacking, stacking multi-layer, Then launched, easy to forklift transported to warehouse storage. The device uses PLC + touch screen control, intelligent operation and management, easy and easy to grasp. Can greatly reduce the labor force and reduce labor intensity.

① Model: XKMD-02

② form: Low Cartesian coordinates palletizing

③ production capacity: 4-5 beats / min (once can pick up 1-4 boxes, according to the size of the carton weight)

④ equipment structure:

Carton or bucket input, sorting device

Catch palletizing or sucker palletizing

Pallet stacking and automatic supply device

Stacking device

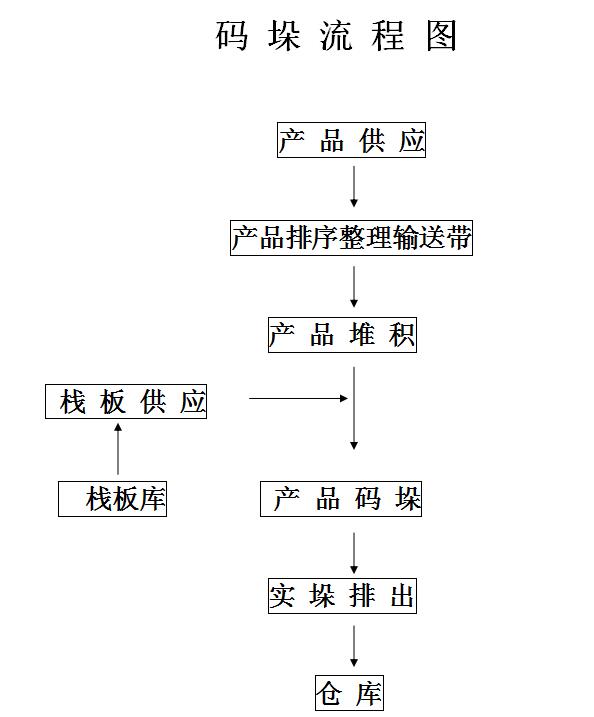

⑤ process:

⑴ carton or barrel input part

Carton or bucket conveyor: According to the arrangement of the compulsory set of cartons or buckets for steering or conveying, in order to achieve finishing, sorting role.

Sorting device: The supply conveyor belt will be finishing the first column of cartons or barrels with a cylinder into the lifting device and then push the second column, the third column to form the sorting layer.

⑵ automatic palletizing device: When the cartons or buckets in a certain order to form a group after the servo motor carrying products rise and move to the upper part of the palletizing device, and steadily on the pallet (or the previous layer) to form Automatic stacking. The palletizing device relies on the servomotor and the chain to complete its lifting, lowering and advancing (retracting).

⑶ part of the pallets

Pallet supply device: Pallets can stack 5-10 empty pallets (according to the weight of the material tray to determine the number), and in accordance with the program requirements to the palletizing equipment supply pallet. Powered by a separate motor.

Pallet output device: When a pallet reaches the palletizing layer, the signal is sent out and the palletizing section is pushed out. The actual stack is delivered to the designated position by excluding the conveyor belt.

⑥ material:

Rack: SS41 (A3 steel spray paint)

Shaft: S45C bearing steel

Roller: double-ended bearing roller (galvanized)

Hood: SS41 (A3 steel spray paint)

Guide plate: SS41 (A3 steel spray paint)

⑦ Features:

The use of touch-screen operation to achieve man-machine dialogue, can show the production speed, the cause of the malfunction and location, a high degree of automation. Using PLC programmable carton or barrel sorting stack layers, pallet supply and discharge can be programmed into the program control.

Mitsubishi PLC and Wei Lun brand touch screen (7 inches) or other imported brands, electrical components in line with international standards, reliable performance, interchangeability, durability and strong.

The use of pneumatic components and cylinders produced by Japan's SMC and Taiwan's ADR customers are of reliable quality and performance.

Security door, hood equipped with electrical sensors, when the cover door is opened, the machine stops working, personnel can be protected.

Stacking adjustment easy, simple, can be carried out on the touch screen.

Stacking stable, efficient, can greatly save manpower.

Carton supply system uses brake motor control, to ensure that pre-set position to deliver cartons or barrels.

Large capacity pallets, can accommodate 5-8 empty pallets, pallet can be automatically supplied.

Low noise in line with China's international standards for noise below 75db.

There are several ways to stack without changing stack parts.

Servo motor Panasonic or Mitsubishi brand, motor reducer Taiwan Sheng state motor brand.

Public consumption:

Power: AC, 3-phase, 380V, 6KW 50HZ

Air consumption: 500NL / MIN (air usage: 5-6kg / cm2)